Chroma Finish

Chroma Finishes are high performance colorants integrated into 100% acrylic polymer finishes formulated with advanced technology for superior fade resistance, improved long-term performance and dirt pick-up resistance.

Chroma Finishes are high performance colorants integrated into 100% acrylic polymer finishes formulated with advanced technology for superior fade resistance, improved long-term performance and dirt pick-up resistance.

View projects featuring Chroma Finish.

As we continue the integration with Sika Corporation, please use this  Product Name Cross Reference Guide to look up the previous Master Builders Solutions product name and the new SikaWall product name. Please contact us if you have any questions.

Product Name Cross Reference Guide to look up the previous Master Builders Solutions product name and the new SikaWall product name. Please contact us if you have any questions.

FEATURES | BENEFITS |

Offers greatly improved color retention compared to conventional finishes | Better appearance; reduced maintenance costs |

Only tinted in the factory to assure the highest product quality | Quality control |

Anti-fade warranty | Peace of mind |

Uses

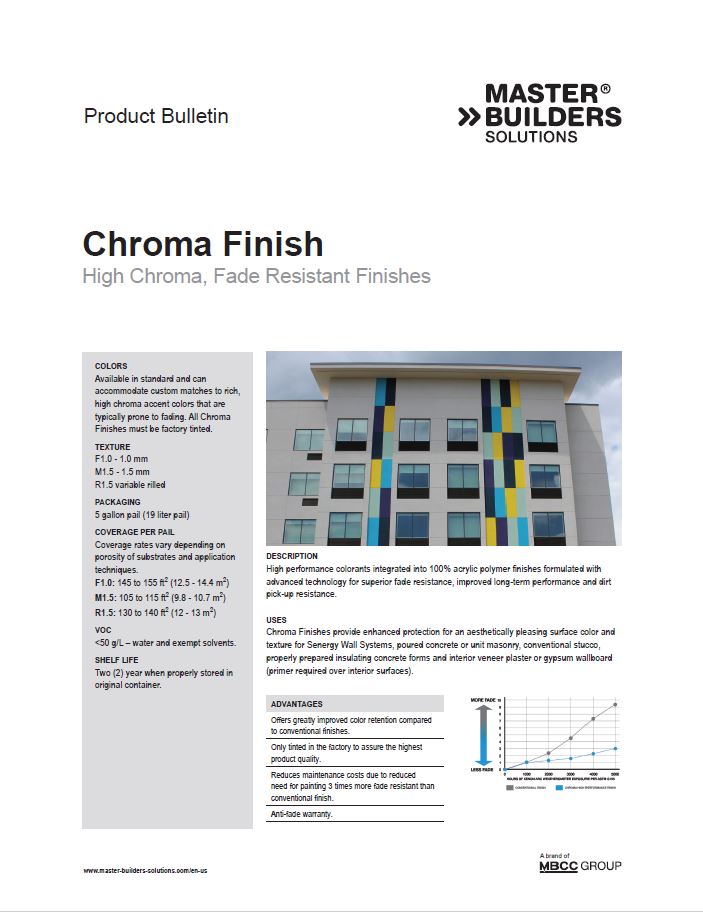

For conventional finishes tinted with typical point of sale (POS) colorants, achieving rich, intense colors has always presented challenges. When design demands the brightest yellows, reds and oranges or the deepest blues, greens and violets, Chroma Finish delivers high definition color that will stand the test of time. Chroma Finish is perfect for bold corporate color schemes or eye-popping graphics. Use over any Senergy wall system or as the finish coat over unit masonry and poured concrete.

Packaging

5 gallon pail (19 liter pail).

Coverage

Coverage rates may vary depending on the coating texture, porosity of substrate and application techniques.

- F1.0 Finish: 125 to 135 ft2 (11.6 - 12.5 m2) per pail

- M1.5 Finish: 105 to 115 ft2 (9.8 - 10.7 m2) per pail

- R1.5 Finish: 125 to 135 ft2 (11.6 - 12.5 m2) per pail

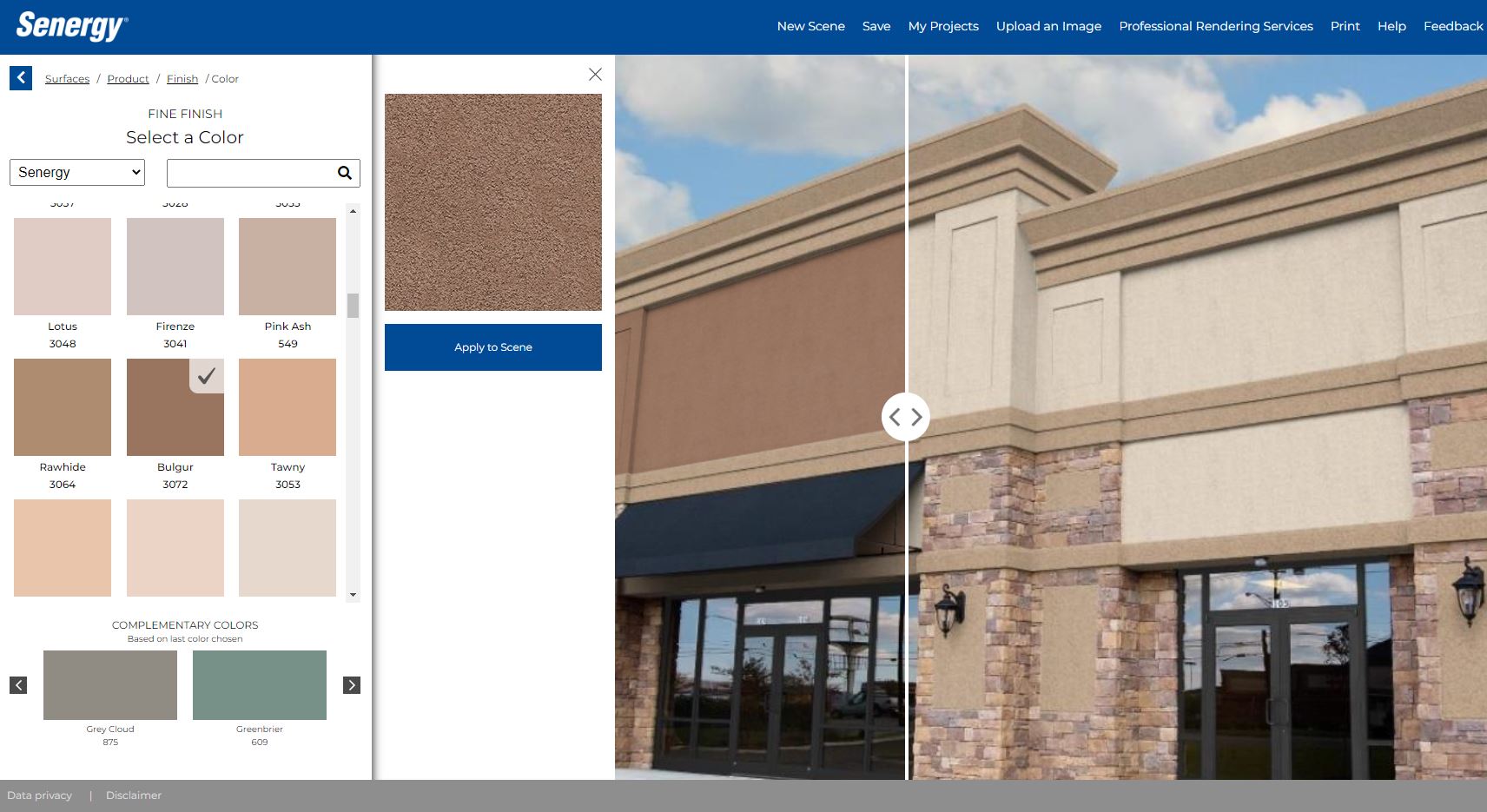

Colors and Textures

View Chroma Finish color chart. All Chroma colors are custom matched to your specifications. Chroma Finish is available in three textures: F1.0, M1.5 and R1.5. System designed specifically to accommodate custom matches to rich, high chroma accent colors that are typically prone to fading.

- F1.0 Finish utilizes uniformly-sized aggregates for a uniformly fine texture.

- M1.5 Finish provides a uniform “pebble” appearance.

- R1.5 Finish has a medium “worm-holed” or rilled appearance which is achieved due to the multiple aggregate sizes in the finish. The “worm-holed” look can be circular, random, vertical or horizontal.